Yamaha 3JH3E and Kanzaki KM3A1 Marine Drive – Clutch Slipping

For a while we have been puzzled.

We would start the port engine and put it into gear. And all would be well.

Then we would stop for whatever reason.

And then we would put it into gear again – and nothing happened. It seemed like the prop wasn’t turning. Indeed occasionally that was the case. But in most cases the prop shaft was still going around.

Yet we were doing just 1.5 kts instead of 3.5 kts, using just the one port engine. And the same would happen in reverse – just no power when we try to maneuver.

Finally we figured out that the clutch must be slipping.

The workshop manual had a whole list of possible causes, but most seemed to do with oil pressure. I guess that the clutch needs oil that is not too thin, and not too thick, in order to work correctly. The gearbox case does specify SAE 30 oil, but a lot of people seem to think that Automatic Transmission Fluid would do the job better. That is most specifically NOT the case. Well, we didn’t have ATF in it, but we did wonder if perhaps the mechanic in Antigua had put the wrong grade in, and that now, when the oil heats up, it would get too thin and no longer work.

The mechanic who took a quick look at it started muttering about replacing the cones for about $1000. Hmm, not keen on that idea.

In any case we were well overdue for a transmission oil change (oops – mea culpa), so I bought the correct grade of oil, changed the oil twice, in order to totally rinse out the old oil, and then filled it up with ‘Genuine Yanmar Transmission Oil – SAE 30’ just to be absolutely sure we had the right stuff.

That was four days ago.

Well, since then we have not had any problems with it slipping. And today we gave it a very good workout which would previously have caused us problems.

So, it looks like it was all fixed with some fresh oil!

Phew.

Update November 2013

Once we were tucked up in Ragusa, we decided it was time to take a proper look at this. Over the summer the clutch has mostly behaved itself, but there were still times when it was slipping.

Further research had revealed that this is actually quite a common problem, caused by the cone on the clutch becoming too polished. The cause of this is too much idling with the clutch out of gear (as when sitting at anchorage charging batteries). It is for this reason, plus the knowledge that idling isn’t good for diesels in general, that we always try to put the engine into reverse gear when charging. This pulls the boat gently back on the anchor, puts some load on the engine, and works well except in the lightest of zephyrs when one then ends up going around the anchor in circles.

Anyway, fixing the clutch is, supposedly, a simple job. Take it apart, lap it down with some carborundum paste (like lapping engine valves in their seatings), and then put it back together. Except that someone in the past had locktited everything together ,so we just couldn’t get the housing off the clutch.

We called in a mechanic who understood the problem. He took it to his shop, took it apart, and ground down the cone. However, he said that this was not the first time it had been done, and that next time around we are going to need a new replacement unit.

He also told us to use ATF oil instead of the normal 30 SAE. This rather surprised us, but he did seem to understand the problem with these units, so I guess we will give it a go. He said that we should do this because of the worn-down state of our cone. Another Yanmer mechanic confirmed that we should do that.

It turns out that this fixed the problem and all is working well now.

How to Remove the Gear Box

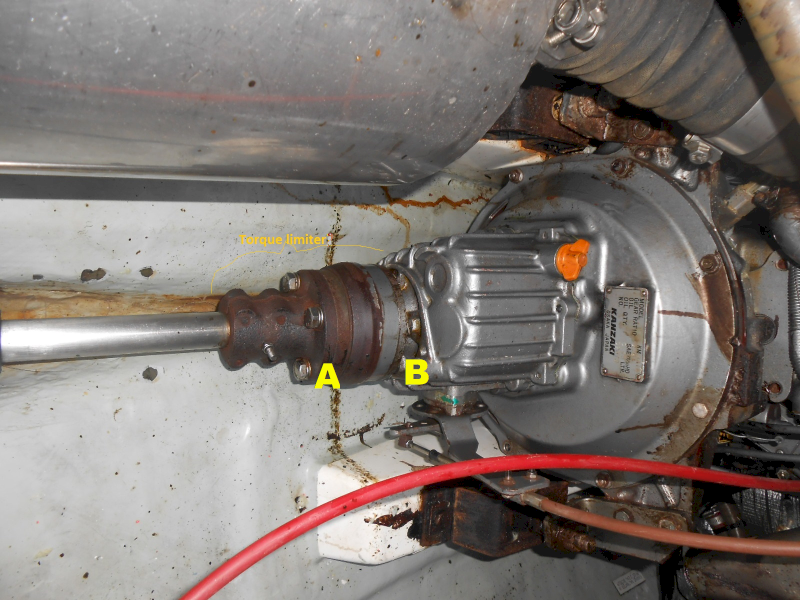

The photo below shows the marine drive assembly. You will see that there is a big chunk labelled Torque Limiter. Not many boats have this, but ours does. The intent was to prevent over-torquing the marine drive when first putting it into gear. It contains a number of discs that operate rather like a clutch – they will slip if too much torque is applied which should also protect one from damaging the gear box with a prop wrap.

Anyway, to take the gear box off, first empty the oil from it.

Then you have to disconnect the torque limiter from the gear box. You do that by undoing the 4 stainless bolts (next to the letter A) of which you can see three above. There are also some bolts on the forward end of the torque limiter, by letter B. Do NOT undo those, as that will take the limiter apart, and you will then have a real struggle getting it all back together again.

Once you have taken out bolts A you have separated the prop shaft form the torque limiter.

You will see inside a big bolt with a huge slot in it. This has a LEFT HAND THREAD. Use something large, like an old U-fitting from a turnbuckle, or some piece of stainless steel plate, that will fit nicely into the slot and onto which you can get some leverage. Then, holding the torque limiter still with a vice grip wedged in, turn that bolt clockwise to undo it. That will separate the torque limiter from the gear box.

Now it is just a matter of removing the blots from around the rim of the gear box, and disconnecting the morse cable controls.

If you need to service the torque limiter itself, read the scarce and hard to find torque limiter_service manual (pdf).

Hi there,

We just had a similar transmission slip issue (today!). Did the “Yanmar brand 30 wt” oil change still solve this problem long term?

We have a 2002 Leopard 42.

Hi Fred,

So far, so good. We have not had any more problems with slip since we changed the oil. Since it is such a small quantity of oil, and since it is so easy to do, I plan to change it each time I change the engine oil.

The key is to find a low profile container that will slide under the transmission to catch the oil. I find that typically whenever I do something on the engine like changing the oil, the actual job takes about 15 minutes, and then cleaning up all the oil spills I made takes me another hour!

Good Luck with it!

Noel

Hi Noel… I became a proud owner of a R&C 42 about a year ago… Now im having a very similar problem with the transmission of the port engine. First time i just removed the oil from previous owner when the transmission started to fail… Then i decided to put SAE 30 oil and at the beginning it worked good… But of course after about 2 months the same problem again. I decided to contact the previous owner and ask him about what oil should i use…. Ad he said, same oil than for the engine. 15W40…. Well, right now it still fine and no slipping… Hopefully still for a long time… But in the worst case, that i have to change the cone… Do you think is it a good idea me to open and replace the cone drive instead and mechanic….? Im usually in the philippines and sometimes (99%) is much more better to do the things by yourself than contracting someone… Thanks

Congratulations on your new boat!

I was unable to open the gear box myself – as in physically unable to – so I had a mechanic do it. It was probably the right thing to do in my case. He told me that the cone was pretty worn down. He did the re-surfacing of the cone, but said that next time it would almost certainly need to be replaced. In the meantime he told me to use ATF oil instead of the SAE30. I confirmed this with a friend of mine who is also a Yanmar engineer. So that is what I did. With the combination of his work on the cone, plus the ATF oil we have, so far, had no more problems with it.

Kanzaki do specify SAE 30, not 15W40, but they also clearly say to NOT use ATF. So what do I know? The rational was that with the cone more worn down we needed a thicker oil.

If you can get the case open, then I believe it is a pretty straightforward job to replace (or grind) the cone yourself.

Best of luck!

Noel

Well… I don’t know if the previous owner did resurfacing of the cone… I think this operation can be done by most of marine engine mechanics as they are very use to do this kind of jobs… Let’s cross the fingers and see how is it going the next months… by the Way it is still working good with the 15W40…

Noel, is there any other concern to be worry about this engine? I’m now in a kind of Drydock and can check here everything very easy… I don’t want to leave and then say…. F**KKKKK, I should have done this before, hahaha. Our engines are about 5000 hours.

Thanks!

Have a 3jh3e Yanmar in our sailboat with the Kanzaki KM3A2 transmission and Kanzaki KM3A1 Torque limiter. Wasn’t even aware that the drum looking device in between the prop shaft coupling and the transmission was a Torque limiter. Need to replace the prop shaft due to crevice corrosion in the area of the cutlass bearing. Since I’m replacing the prop shaft and shaft coupling, I was looking at the SigmaDrive CV joint that can replace the shaft coupling which is when I recognized a need to identify what the torque limiter is, and ended up reading your post, and the linked service manual. I have been advised that it would be best to just eliminate the Torque Limiter entirely since I am getting a new prop shaft, and lengthen it. Contacted Kanzaki Corp in Japan who referred me to USA based Yanmar service representatives. Our local Yanmar Service Manager, replied that “You can do away with the limiter. Most Engines don’t even have a limiter, so if its removed it certainly will not hurt anything.”. I was curious what your take about the advocacy of removing the Torque Limiter, given the service manual seems to indicate that shifting from reverse to forward under power can result in high loads and damage to the transmission. They are nearly impossible to find if one needs replacing, and cost over $2K for the assembly. One opinion I received was that removal would actually result in increased reliability. I certainly don’t want to remove the Torque Limiter if it could result in having to rebuild my transmission. Really would have liked Kanzaki to have provided support!